On-demand customization, intelligent production –ShangGong garment intelligent manufacturing micro factory

With the rapid economic development and clothing aesthetic concept gradually mature, people comfortable fit to clothing, high quality, high grade, personalized demand is higher and higher, to speed up the combination of a new generation of information technology and garment industry, introduce "on-demand customization" C2M business model, promote clothing manufacturing industry to develop in the direction of digital, intelligent and flexible, personalized and mass customization will become the development trend of garment industry.

ShangGongGroup (stock code: 600843, 900924) actively embraces new opportunities for changes in the times, based on its strong equipment and technical strength, is committed to changing the traditional production mode, and provides demonstration models and integrated solutions for "customization on demand" to create a two-way platform of "personalized customization + intelligent manufacturing"-ShangGong garment intelligent manufacturing micro-factory.

ShangGong garment intelligent manufacturing micro factory is located in Jinqiao Export Processing Zone, Pudong New Area, Shanghai. At present, the factory can "customize" suits, trousers, shirts, jeans and other styles of business formal and casual wear.

The factory uses specialized and automated equipments such as Shanggong, Dürkopp Adler, PFAFF Industrial, Mauser,Richpeace and its partner German VEIT ironing, greatly improves work efficiency, shortens production cycle, reduces labor cost and ensures excellent and stable sewing quality.

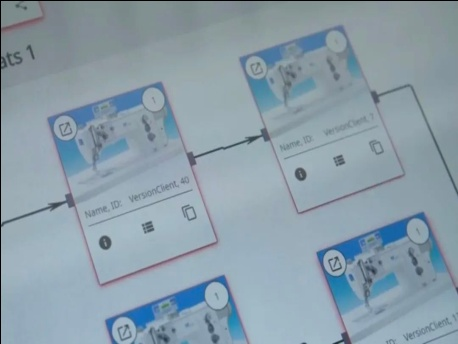

The factory introduces Sanhe intelligent transmission and sorting system, Yina intelligent hanging system and Huansi MES production e.xecution system and other information software and hardware supporting equipment, and applies the QONDAC industry 4.0 network system developed by ShangGong Group in Germany, uses big data means to complete the whole domain connection between factors of production, realizes the production and application scenarios of the Internet of Things.

German QONDAC industry 4.0 network system can effectively solve the interconnection between sewing equipment, real-time monitoring of the production equipment and perception of bottlenecks in the production process through the visual management of the production system,optimizing the order plan, while the system also has the equipment remote fault diagnosis and predictive maintenance functions.

MES as smart factory production process is the core of the system, based on the intelligent transmission, intelligent hang and QONDAC system of quantitative data acquisition, process scheduling, workshop in detail planning and production scheduling management, production process control, and other functions to achieve intelligent manufacturing process optimization, digitizing, transparency and full traceability, so as to achieve intelligent and fine management.

The digital transformation of the manufacturing industry is a strategic-led business transformation, combining with the clothing business pain points, ShangGong Group promotes the two-way integration of business and systems, with digitalization as the core, automation equipment as the support, and networked means to achieve intelligent empowerment, providing demonstration models and integrated solutions for "customization on demand" and creating more value for customers!

[Contact us]

If you have cooperation intention/customized demand/production demand, you can directly contact 021-68407700 to make an appointment for visit and negotiation.

品/logo/da.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/pfaff.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/tjfy.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/ksl.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/hd.png&w=104&h=68&mode=fill&bgcolor=)