SpaceX Spacesuit made by PFAFF Ultrasonic Welding Machine helped propel the First Commercial Manned Flight

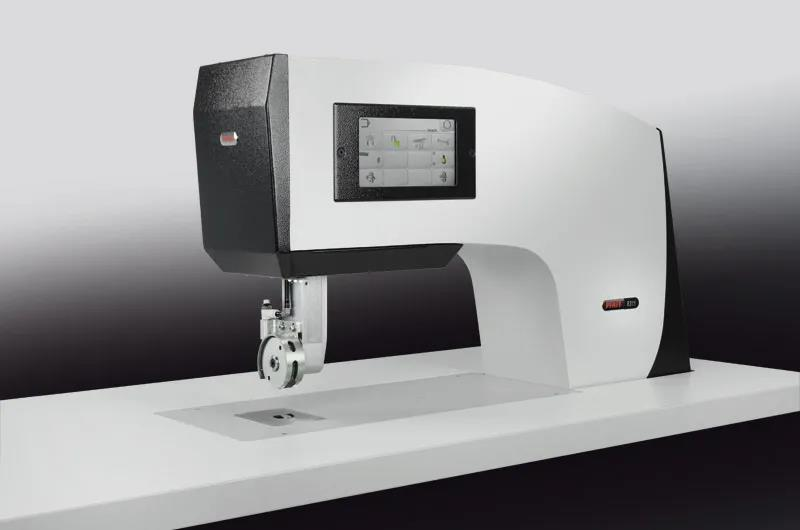

On the afternoon of August 2nd, US Eastern Time, after staying on the International Space Station for two months, the "Dragon" spacecraft of the space exploration technology company SpaceX successfully returned to Earth and completed NASA's first commercial manned mission. SpaceX's new spacesuit is made by the PFAFF 8310/8311 ultrasonic welding machine of Germany's PFAFF, a subsidiary of Shang GongGroup. Its functional seams fully meet the strength and tightness required for working under extreme conditions in outer space!

From head to toe, black and white lines, close-fitting, full of high-energy black technology, while pursuing minimalism, the "Dragon" spacecraft spacesuit not only embodies SpaceX's unique style, Musk's aesthetic taste, but also successfully passed NASA's various A rigorous test, 100% meets the requirements of safety, functionality, and adaptability! It is not a simple task to complete this extraordinary space suit that combines fashion and safety, highlighting strength and taste, and who can stand it? The protagonist with his own halo is here:

Unique features:

Unparalleled attributes: continuous welding and monitoring of welding force

Innovative two-wheel system: start the cutting wheel by motor

New function: multifunctional platform suitable for various options

-Motorized tug wheel

-Simple parallel mop wheel

-Illumination from above and below (lower level visualization)

-Joint cooling device (from above and below)

-Cross marking laser to ensure accurate starting position

Intelligent function: seam edge detection, layer detection (such as cross seam)

Brand new touch screen (processing through simple icons)

All the proven functions of the existing ultrasonic welding machine are included in the new machine concept

PFAFF has more than 30 years of experience in rolling-feed ultrasonic welding. In addition to adjusting the speed and welding energy, 8311 can also detect and automatically correct the pressure during the welding process and keep it constant, and set the gap between the pressure roller and the ultrasonic vibration wheel-full Unique in the world, pioneered by PFAFF, it is also a major leap forward in textile ultrasonic welding. Since its establishment in 1862, PFAFF has always been committed to providing tailor-made sewing and welding solutions for clothing, automobiles, filters, mattresses, home textiles, aerospace and other fields, and is the most powerful partner for complex applications and specific needs!

品/logo/da.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/pfaff.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/tjfy.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/ksl.png&w=104&h=68&mode=fill&bgcolor=)

品/logo/hd.png&w=104&h=68&mode=fill&bgcolor=)